X7

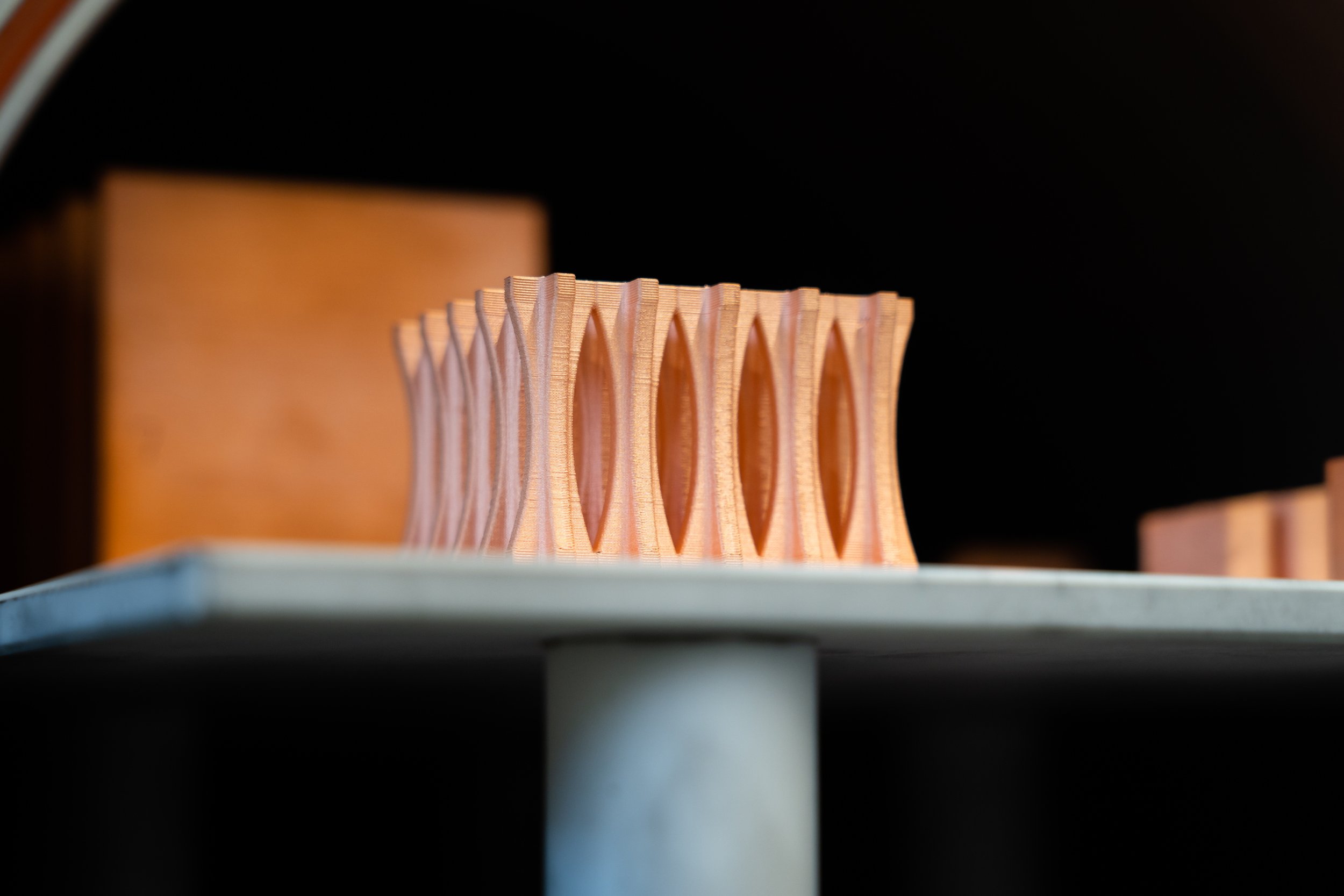

A game changing way to get industrial-grade parts in hours, not weeks — the X7 carbon fiber 3D printer enables United Machinists to offer clients a fundamentally improve manufacturing operations at light speed.

The X7 3D prints Continuous Carbon Fiber reinforced parts in hours that can be as strong as — and capable of replacing — machined aluminum. It also allows for a wide variety of functional requirements such as flame resistance, chemical resistance, energy absorbance, high resolution and draft parts.

Precision-machined hardware, advanced sensors, and unique software drive leading edge accuracy and reliability for our clients. Markforged industrial carbon fiber 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with high repeatability and near-perfect surface finish.

Build Volume:

Width 330mm | Depth 270mm | Height 200mm

Compatible Materials:

Onyx™

Onyx ESD™

Onyx FR™

Nylon

Precise PLA

Carbon Fibre

Fibreglass

Aramid Fiber (Kevlar®)

HSHT Fibreglass

Printing Process: Continuous Fiber Reinforcement (CFR)

Printing Media: Composite Base Filaments, Continuous Fibers